In modern construction and industrial projects, selecting the right structural materials directly impacts the project’s durability, safety, and overall cost. As a specially anti-corrosion treated steel product, galvanized angle steel has become an ideal choice for numerous projects due to its outstanding performance. This article will deeply analyze the advantages, application scenarios, and selection key points of galvanized angle steel to help you make informed decisions during project planning.

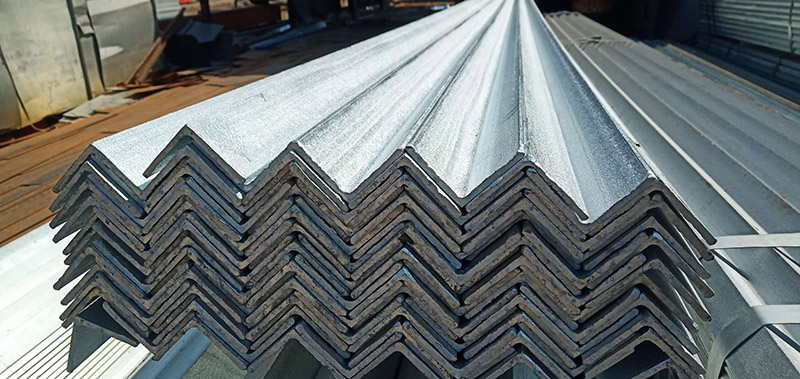

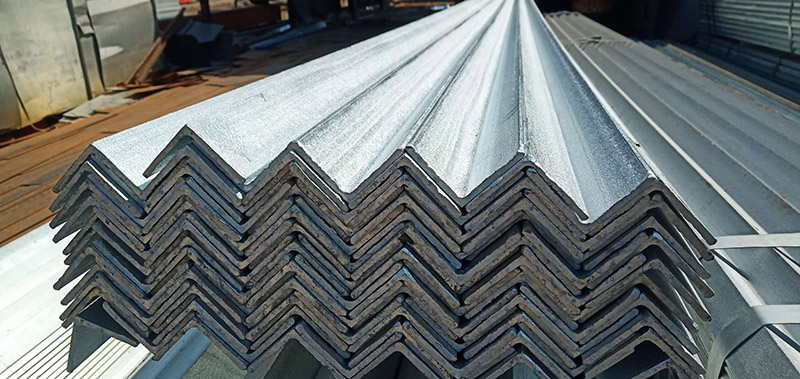

Galvanized angle steel is a profile made by applying a zinc coating to the surface of ordinary carbon structural steel or low-alloy high-strength structural steel angle steel. According to different galvanizing processes, it is mainly divided into two types:

Hot-Dip Galvanized Angle Steel: After derusting, the angle steel is immersed in molten zinc solution at approximately 500°C, forming a uniform and dense zinc coating on the steel surface. The coating thickness is usually over 85μm, providing excellent anti-corrosion effects.

Electro-Galvanized Angle Steel: A zinc coating is deposited on the surface of the angle steel using electrochemical principles. The zinc coating is thinner but has a smoother surface, making it suitable for scenarios with high appearance requirements and mild corrosive environments.

Whether it is equal-sided angle steel (with equal width on both sides) or unequal-sided angle steel (with different widths on the two sides), galvanizing treatment can significantly enhance its corrosion resistance.

The zinc coating forms a physical barrier that effectively isolates the steel from air, moisture, and other corrosive media. In general environments, hot-dip galvanized angle steel can have a service life of 30-50 years, greatly reducing maintenance costs and replacement frequency.

Galvanizing treatment does not affect the original mechanical properties of the steel. The angle steel still maintains its inherent high strength and rigidity, enabling it to bear large loads and making it suitable for various load-bearing structures.

Although the initial purchase cost of galvanized angle steel is higher than that of ordinary angle steel, its ultra-long service life and minimal maintenance needs result in substantial long-term cost savings.

Galvanized angle steel does not require on-site anti-corrosion treatment and can be directly installed, simplifying the construction process. Its diverse specifications (ranging from 25×3mm to 100×8mm, etc.) can meet the design needs of different projects.

The silver-gray zinc coating surface not only has an industrial aesthetic but can also be repainted as needed, balancing functionality and decorativeness.

With its unique properties, galvanized angle steel is widely used in multiple fields:

Building Structures: Curtain wall supports, steel structure frames, roof brackets, etc.

Infrastructure: Power transmission towers, communication base stations, street lamp poles, traffic guardrails.

Warehousing and Logistics: Shelving systems, storage cages, logistics equipment frames.

Municipal Engineering: Sewage treatment facilities, urban pipeline brackets, public facilities.

Agricultural Sector: Greenhouse frames, agricultural machinery equipment.

Shipbuilding: Ship cabin brackets, deck components.

Select the Process Based on the Environment: In humid, coastal, or industrial corrosive environments, prioritize hot-dip galvanized angle steel; electro-galvanized angle steel can be considered for dry indoor environments.

Clarify Specification Parameters: Determine the side length and thickness of the angle steel according to load-bearing requirements, with reference to relevant engineering design standards.

Focus on Quality Standards: High-quality galvanized angle steel should comply with GB/T 13912-2018 (hot-dip galvanizing standard) or corresponding international standards, with a uniform zinc coating, no missing plating, and no bubbles.

Choose a Reliable Supplier: Ensure the product comes from a formal manufacturer, which can provide quality inspection reports to guarantee stable material performance.

With its excellent anti-corrosion performance, high strength, and cost-effectiveness, galvanized angle steel has become an indispensable structural material in modern engineering construction. Whether for large-scale infrastructure projects or small industrial installations, selecting the right galvanized angle steel can provide solid support for the long-term stable operation of the project.

If you are looking for a reliable structural solution for your next project, consider the multiple advantages of galvanized angle steel. For more product specifications or application cases, please contact our professional team for customized advice.