The production process of galvanized plates generally includes raw material preparation, cleaning, pretreatment, galvanizing, post - processing, inspection, and packaging. The specific introduction is as follows:

Raw material preparation: Prepare carbon steel plates as the base material, usually cold - rolled or hot - rolled steel plates. The surface of the steel plates needs to be pretreated to remove oil, rust, and other impurities.

Cleaning: Pickle the steel plates to remove surface oxides and other contaminants. Commonly used pickling solutions are hydrochloric acid and sulfuric acid. The pickling time and temperature should be controlled within a certain range to avoid damaging the steel plates.

Pretreatment: Perform pre - plating treatment on the cleaned steel plates. Common methods include pickling phosphating and alkali phosphating. Pickling phosphating is to soak the steel plates in a solution containing phosphates and pickling agents to form a phosphate chemical film, improving the adhesion of the coating. Alkali washing phosphating is to immerse the steel plates in a solution containing alkaline detergents and phosphates, which can also form a phosphate chemical film.

Galvanizing: Immerse the pretreated steel plates in a molten zinc solution and deposit a zinc layer on the surface of the steel plates through the action of electric current. Galvanizing methods mainly include hot - dip galvanizing and electro - galvanizing. Hot - dip galvanizing is to immerse steel plates in molten zinc to form a zinc layer by reacting with the steel plate surface. Electro - galvanizing is to deposit zinc ions in the zinc solution on the steel plate surface by electrolysis to form a zinc layer. The hot - dip galvanized coating is generally thicker and has better corrosion resistance, while the electro - galvanized coating is thinner but more uniform.

Post - processing: After galvanizing, the galvanized sheets need post - processing, including cooling, slag removal, and surface treatment. Cooling is to take out the galvanized sheets from the molten zinc and cool them naturally or with water. Slag removal is to remove the zinc slag on the galvanized sheets to improve the surface quality. Surface treatment includes drying, trimming, and oiling to protect the surface of the galvanized sheets from contamination.

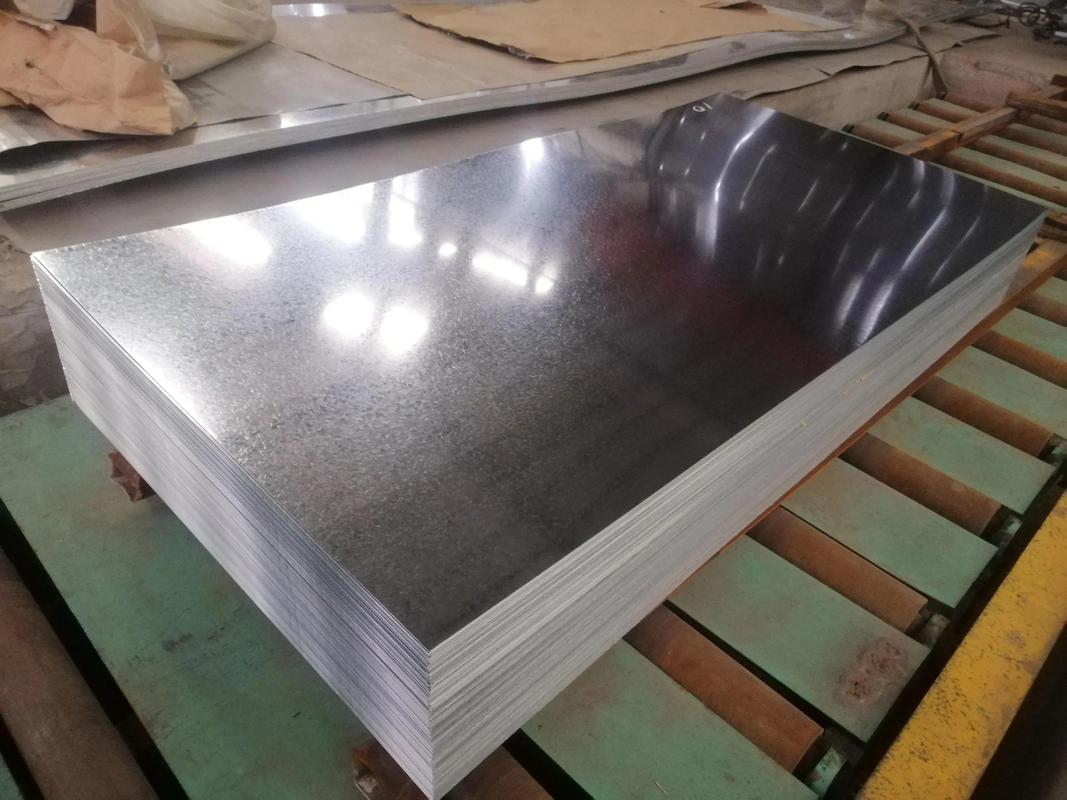

Inspection and packaging: Conduct quality inspection on galvanized sheets, including the inspection of coating thickness, adhesion, appearance quality, and other indicators. Qualified galvanized sheets can be used in various fields such as construction, home appliances, and automobiles after packaging.